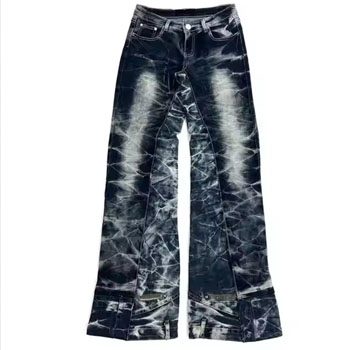

Men's loose stack bell-bottom denim Monkey wash jeans manufacturer

['$']Customized demand quotation

Customization Overview

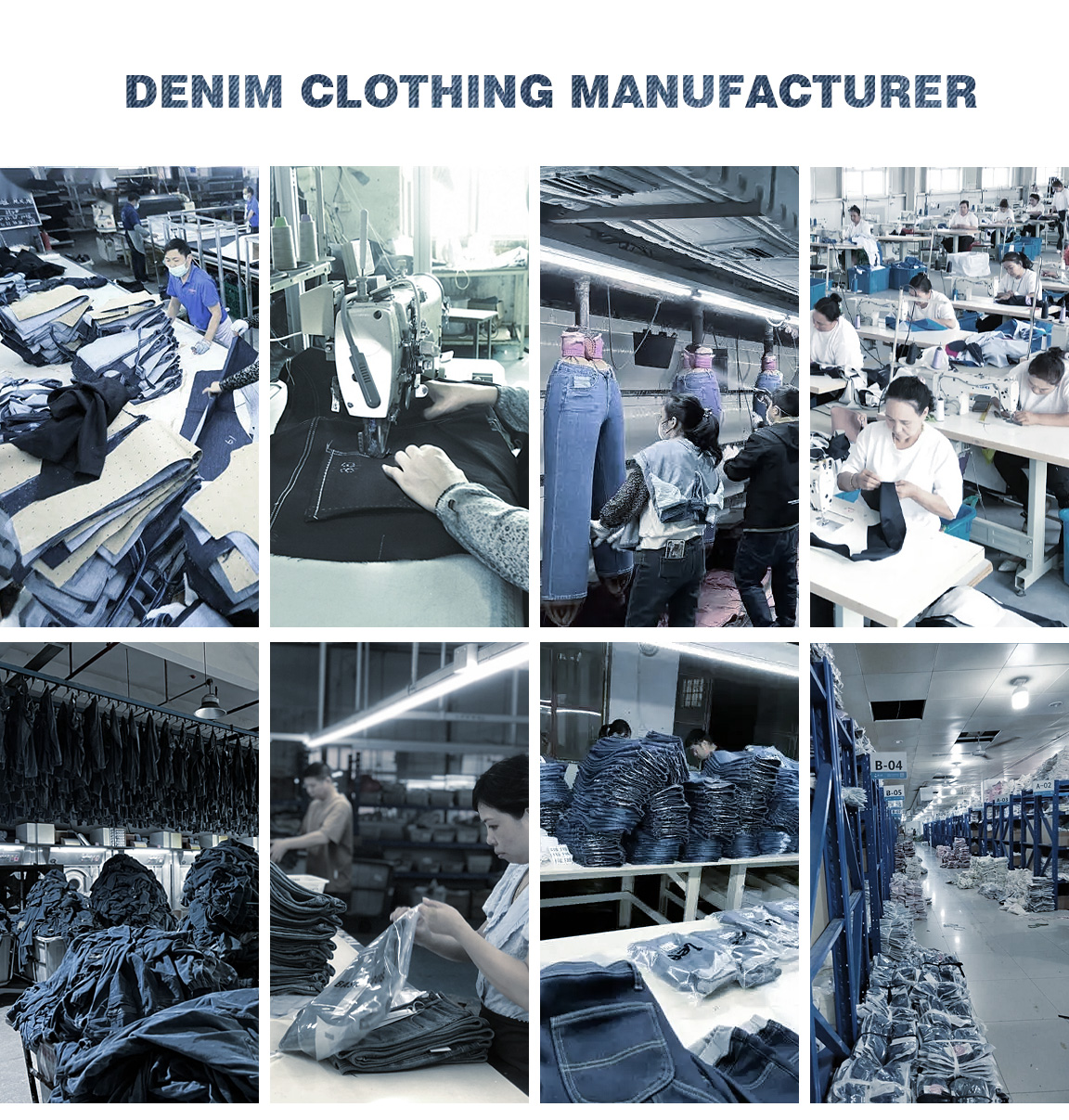

Specializing In Denim Clothing Manufacturing,our Design The Style Which Customer Wants And Complete The Complex, Customized Process.

Our factory has 10 years of experience in research and development, production and sales of high quality, cost effective sportswear factory area over 2000 m².

we also undertake a great many customized orders from all over the world.

We have a strong design team, development team. They can design the style which customer wants and complete the complex, customized process.

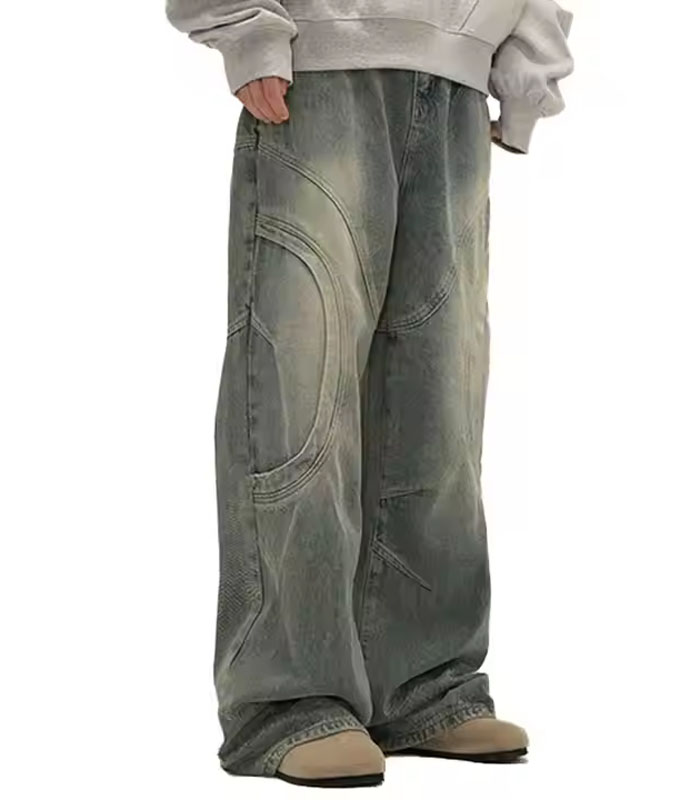

The resurgence of retro fashion has brought men’s loose stack bell-bottom denim back into the spotlight, with Monkey Wash techniques adding a unique vintage appeal. As a leading bell-bottom jeans manufacturer, we specialize in crafting high-quality, fashion-forward denim that blends 70s-inspired silhouettes with modern distressed finishes.

What Are Monkey Wash Jeans?

Monkey Wash is an advanced denim treatment that combines stone washing, enzyme softening, and hand abrasion to create a naturally faded, high-contrast vintage look. Unlike standard stone washing, this method enhances texture and whiskering for a more authentic worn-in feel.

Manufacturing Process of Loose Stack Bell-Bottom Denim

1. Premium Denim Selection

Fabric: Heavyweight (12-14 oz) 100% cotton or cotton-blend denim for durability and optimal stacking.

Cut: Relaxed fit through the thigh, flaring into a dramatic bell-bottom silhouette for a retro yet stylish drape.

2. Pattern Making & Sewing

Loose Fit Construction: Designed for comfort with extra room in the seat and thighs.

Stack Effect: Longer inseams create natural stacking above the shoe, enhancing the vintage aesthetic.

Reinforced Stitching: Double-stitched seams and bar-tacking at stress points ensure longevity.

3. Monkey Wash Treatment

Stone Washing: Initial tumbling with pumice stones to soften fabric and create base fading.

Enzyme Wash: Bio-polishing enzymes further break down fibers for a buttery-soft hand feel.

Hand Sanding & Spraying: Artisans manually distress knees, thighs, and hems for a custom, high-contrast fade.

Bleach Spotting (Optional): Targeted bleach applications add unique vintage character.

4. Quality Control & Finishing

Final Wash & Softening: Ensures maximum comfort and shrinkage control.

Metal Hardware: Antique-finish buttons, rivets, and zippers for a cohesive retro look.

Inspection: Each pair is checked for consistency in wash, fit, and detailing.

Why Choose Our Bell-Bottom Jeans Manufacturing?

✔ Custom Washes: Monkey Wash, acid wash, or laser distressing available.

✔ Sustainable Options: Eco-friendly dyes, water recycling, and organic cotton upon request.

✔ OEM/ODM Services: Private labeling, custom fits, and bulk production for brands.

Conclusion

Our men’s loose stack bell-bottom denim combines nostalgic design with expert Monkey Wash techniques, delivering a premium product for fashion-forward brands. Whether you’re looking for distressed retro jeans, relaxed-fit flares, or custom denim manufacturing, we provide high-quality craftsmanship tailored to your needs.

Contact us today to discuss your denim production project!

about specializing in casual clothes, outdoor clothes,Made To Order Guide,Custom Men's Denim,Men's Denim Jackets & Coats,Men's Denim Overalls & Jumpsuits,Men's Denim Shirts,Men's Denim Shorts,Men's Jeans,Men's Denim Set,Custom Women's Denim,Women's Denim Dresses,Women's Denim Jackets & Coats,Women's Denim Overalls & Jumpsuits,Women's Denim Sets,Women's Denim Shorts,Women's Denim Skirts,Women's Denim Tops,Women's Jeans,

We have a strong design team, development team. They can design the style which customer wants and complete the complex, customized process.

At the same time, we also undertake a great many customized orders from all over the world.

Our company has custom for many well-known brands at China and other countries. Get unanimous praise and recognition from customers and establish long term strategic partnerships with many customers.

Our factory has 10 years of experience in research and development, production and sales of high quality, cost effective sportswear factory area over 2000 m². Factory has more than 200 employees.

And there are pre shrinkage machine, jujube machine, forehead machine, reinforcement machine for needle six thread machine, automatic elastic machine, lock Machine, automatic color machine, thread Cutting Machine, and other professional machines. The monthly output is 500,000 pcs.

Our company has always been adhering to the principle of details decide everything, innovation cast the future, innovation as the core, change the traditional standardized simple sales model to provide customers with personalized quality services.

At present, our companies constantly optimizing products, taking thoughtful service as the basic business philosophy and always adhere to provide customers with high quality innovation cost effective sports and leisure clothes.